If your company relies on a third-party logistics provider (3PL) to manage freight, you probably expect that the charges passed through are accurate. But many logistics and finance teams discover, often too late, that they’ve been paying for incorrect shipments, duplicate invoices, or charges that don’t match their contracts.

The process designed to catch those issues is called 3PL freight reconciliation. If you’re not doing it, or not doing it consistently, your transportation spend may be inflated without your knowledge.

This guide unpacks what 3PL freight reconciliation really is, why it matters to your bottom line, and what it looks like when done right.

Key Takeaways

- 3PL freight reconciliation is the process of validating third-party logistics invoices by comparing them to actual shipment data and contracted carrier rates.

- Reconciliation supports supply chain cost control by improving logistics cost visibility, financial reporting accuracy, and vendor accountability.

- Zero Down’s freight reconciliation process can lead to 2–8% in shipping cost recovery, especially for businesses with high shipping volumes.

What Is 3PL Freight Reconciliation?

3PL freight reconciliation is the process of comparing freight charges from your logistics provider to your shipment records and carrier contracts. The goal is to verify invoice accuracy, resolve discrepancies, and identify opportunities for shipping cost recovery.

This is not a surface-level check of invoice totals. Done correctly, a reconciliation process will:

- Match each shipment’s weight, service level, and destination to your internal order or manifest data

- Compare billed rates to what your contracts actually allow

- Flag billing for canceled, delayed, or modified shipments, including ghost shipments

- Catch duplicate invoice entries or repeated accessorial charges

- Reveal gaps between what your 3PL was charged and what they passed through to you

While some teams perform periodic freight invoice audits, 3PL reconciliation is a more complete control process that brings visibility across your operations, finance, and vendor management. It protects against billing leakage, keeps budgets on track, and ensures your transportation data is reliable enough for strategic decision-making.

Why Freight Reconciliation Matters

Freight invoices are dense. Between base rates, fuel surcharges, minimums, DIM weight, and zone-based pricing, even a small error, multiplied over thousands of shipments, can make a material impact on your supply chain costs.

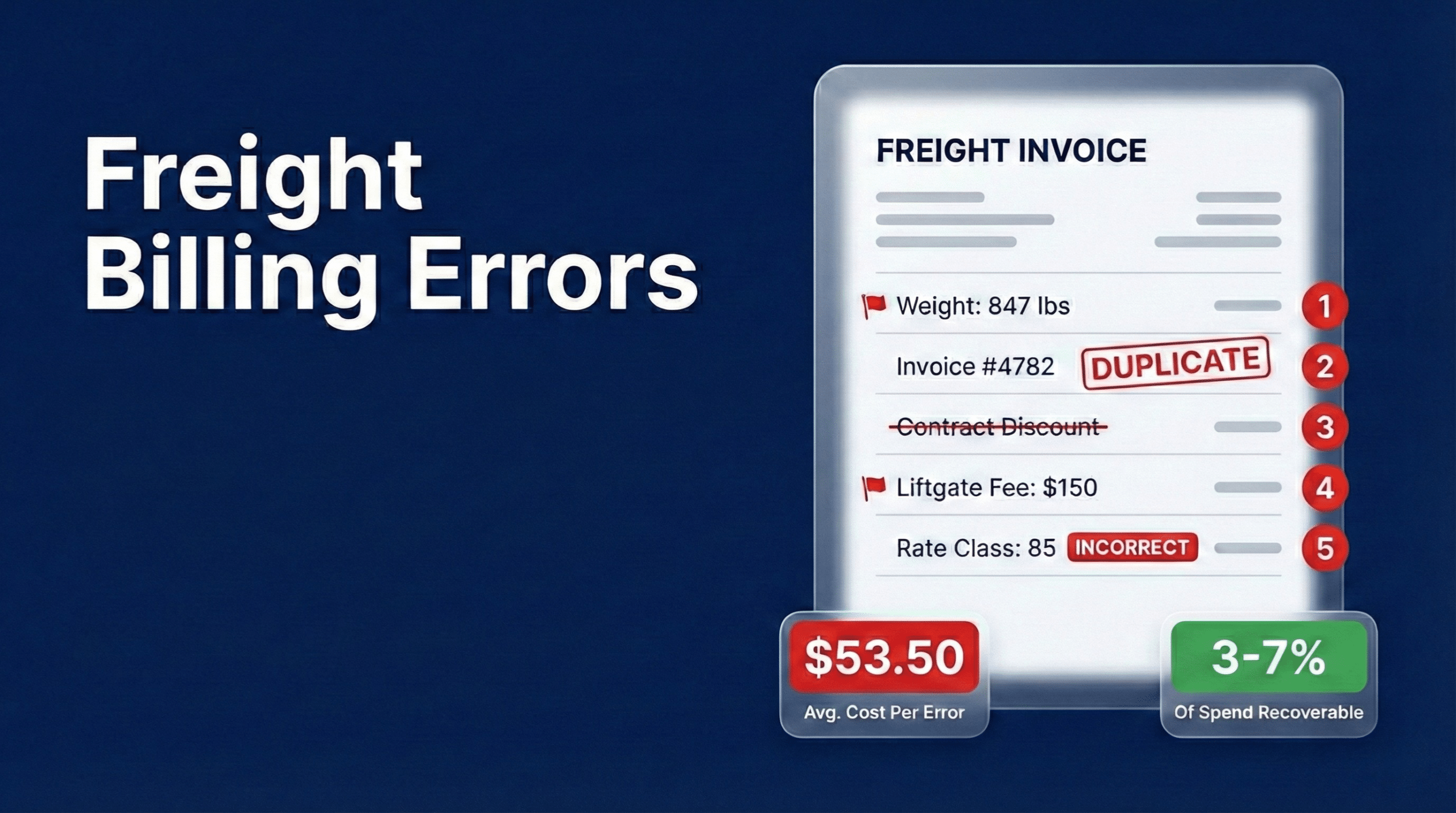

These problems aren’t theoretical. Common issues uncovered during reconciliation include:

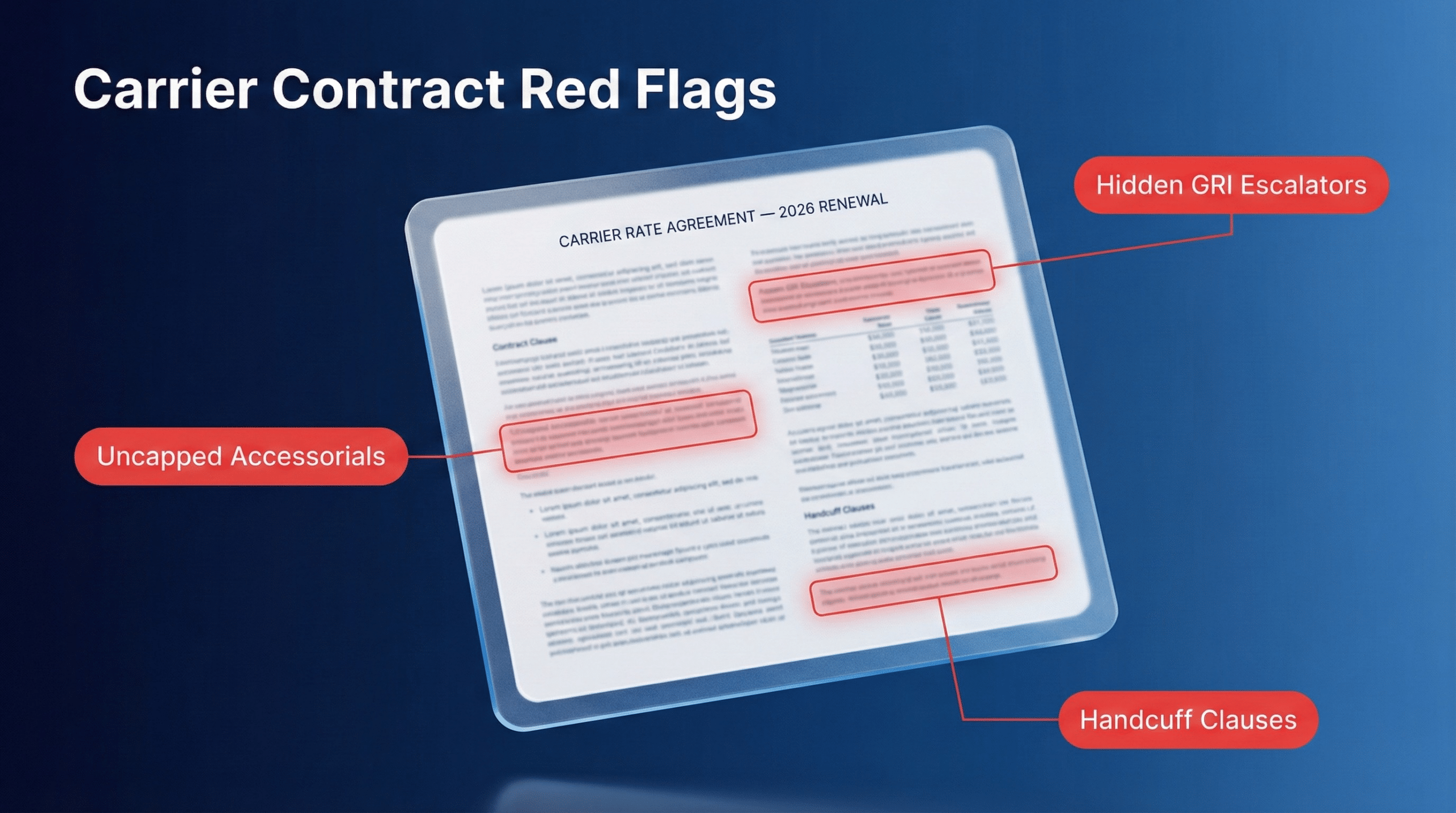

- Contract Non-Compliance: Billing that ignores specific contractual terms, such as agreed-upon FAK rates, leading you to pay a higher class rate than negotiated.

- Phantom Accessorials: Charges for freight services not rendered. This frequently includes fees for residential delivery to a commercial address with a loading dock, or liftgate service when none was required or used.

- Incorrect Dimensional (DIM) Weight Calculations: Even minor discrepancies in shipment dimensions can trigger significant price increases. Reconciliation catches instances where the wrong DIM factor was applied or where dimensions were recorded inaccurately.

- “Ghost” Shipments: Invoices for shipments that were created in a TMS but were ultimately cancelled or never picked up by the carrier.

- Duplicate Invoices: Identical charges appearing across different billing cycles, a surprisingly common error in automated billing systems.

Each of these issues on its own might seem minor. But across hundreds or thousands of shipments, they accumulate, creating real budget impacts and obscuring your actual cost of goods sold.

What a Strong Freight Reconciliation Process Looks Like

An effective freight reconciliation process brings together your internal shipment data, your carrier rate agreements, and your 3PL’s invoicing. From there, it uses both automation and analysis to review each line item and ensure:

- Your shipment data matches invoiced activity

- Charges reflect contractual terms, not default rates

- Invoices are free from duplication, delays, or unauthorized adjustments

- Carrier accessorials are valid and applied according to shipment details

- Any variances are tracked, resolved, and, if needed, disputed

A strong process doesn’t just flag issues after the fact. It reduces data latency by reconciling charges as close to billing as possible, so discrepancies can still be resolved within carrier and 3PL dispute windows (usually 30-60 days) for better resolutions.

It also supports accountability. With accurate records in hand, logistics teams can monitor carrier performance, flag recurring overcharges, and hold partners to contract terms, bolstering 3PL invoice accuracy and long-term vendor relationships.

The Benefits of 3PL Freight Reconciliation for Shippers

For shippers, freight reconciliation is not just about correcting invoice mistakes. It is a tool for gaining control over transportation costs. By comparing what was billed to what actually shipped and what should have been charged, businesses can protect margins, improve planning accuracy, and strengthen accountability with 3PLs and carriers.

Here is what an effective reconciliation process can deliver.

Financial Accuracy

Validated invoices create cleaner general ledger entries, reliable audit trails, and fewer end-of-quarter surprises. For controllers and CFOs, reconciliation provides a level of financial control that’s hard to replicate with manual spot checks or fragmented data.

Shipping Cost Recovery

Reconciliation uncovers real dollars. Many companies recover between 2–8% of their total freight spend simply by catching billing errors and overcharges that were previously overlooked.

Reliable Budgeting

When charges align with contract terms and shipment activity, forecasts improve. Reconciliation enables you to build transportation budgets with confidence and reduce the risk of mid-year reforecasts due to freight drift.

Logistics Cost Visibility

With integrated reporting, your team can see where costs are accumulating, which lanes are most error-prone, and how frequently carriers deviate from contracted rates. This visibility helps drive decisions in routing, service selection, and contract negotiations.

Operational Efficiency

Without automation, teams are often stuck with manual freight reconciliation processes, like reviewing line items by hand, chasing down shipment data, and managing disputes across multiple systems. Automating this process streamlines both AP and operations, freeing up your team to focus on higher-value work and saving on administrative costs.

How Zero Down Helps You Reconcile Costs

For most businesses, building and maintaining a full reconciliation process in-house is a heavy lift, especially when freight volumes are high, carrier mixes are complex, and resources are stretched.

That’s where Zero Down comes in.

We provide managed freight audit and payment services with built-in reconciliation support. Our team combines decades of freight audit experience with our proprietary business intelligence platform, FreightOptics®, to deliver:

- Seamless integration with your carrier, 3PL, and ERP data

- Automated invoice matching and shipment re-rating

- Exception handling with full dispute management

- Centralized dashboards for financial and operational insight

- Ongoing support for budgeting, accruals, and reporting alignment

Whether you need monthly visibility or continuous oversight, our automated freight reconciliation workflows scale with your business and give your team back time, clarity, and control.

Take Control of Freight Costs With a Smarter Reconciliation Strategy

Freight charges are rarely straightforward. Without a reliable reconciliation process in place, it’s easy for billing errors, misapplied rates, or unshipped orders to slip through, significantly impacting your budget, margins, and visibility.

A structured freight reconciliation approach helps you prevent those issues before they scale. It gives your logistics and finance teams the data clarity they need to make informed decisions, protect cash flow, and hold partners accountable.

Zero Down specializes in helping shippers do exactly that. Our team and technology are purpose-built to take this work off your plate while delivering significant cost savings and improved cost control.

If you’re ready to close the loop on your freight spend, we’re here to help you get started quickly and painlessly.

Ready to start saving? Contact our team today.

FAQ

What’s the difference between a freight post audit and 3PL freight reconciliation?

A freight post audit typically focuses on checking carrier invoices for rate and service accuracy. Third-party freight reconciliation goes further by aligning those invoices with your shipment records, carrier contracts, and what your 3PL billed you, creating full visibility and accountability.

How much can shippers typically recover through reconciliation?

Most companies recover between 2–8% of their total shipping spend by identifying overcharges, duplicate billing, and other freight bill errors. The amount depends on volume, complexity, and how often reconciliation is performed.

Can this process work if we use multiple 3PLs or carriers?

Yes. Reconciliation is especially valuable for companies managing freight across multiple 3PLs, modes, or regions. It helps unify data, eliminate inconsistencies, and ensure each provider is billing correctly.

Is this a one-time audit or an ongoing service?

It can be both. While a one-time reconciliation can uncover issues quickly, ongoing reconciliation provides continuous oversight and supports long-term cost control and budget accuracy.

How does Zero Down integrate with our existing systems?

Zero Down connects with your carriers, 3PLs, TMS, ERP, or accounting systems to automate the reconciliation process. We handle onboarding and data integration, so your team sees the results without taking on extra workload.