Freight claims management refers to the process of resolving issues like damage, loss, or delay during shipping to recover costs and improve supply chain performance.

When shipments go wrong—and they inevitably will—your ability to respond quickly and effectively determines more than just the refund. It shapes your customer relationships influences future carrier decisions, and impacts your bottom line.

But freight claims aren’t only about fixing what broke. They can also offer insight into why problems happen in the first place. When managed well, claims data becomes a powerful tool for improving packaging, choosing better carriers, and tightening up internal processes for better service quality.

In this guide, we’ll break down how freight claims management works, why it matters more than ever, and what steps you can take to make the entire process faster, smarter, and more cost-effective.

Key Takeaways

-

Freight claims management is more than cost recovery. It’s a way to reduce waste, improve reliability, and strengthen your entire supply chain.

-

A structured, repeatable process improves accuracy, shortens resolution times, and lightens the workload for internal teams.

-

Real-time claims data helps prevent recurring issues, optimize carrier performance, and guide smarter logistics decisions.

-

A centralized freight claims solution enables faster recovery, better visibility, and fewer costly manual steps.

What Is Freight Claims Management?

At its core, freight claims management is about recovering value and preventing future losses. But it’s not just a back-office task. It’s a critical part of running a reliable, cost-efficient shipping operation that capitalizes on every opportunity to save when shipping incidents occur.

That starts with knowing what kinds of issues qualify for a claim and how to handle them consistently. Most freight claims fall into four main categories:

-

Damage Claims: Products arrive visibly or internally damaged.

-

Loss Claims: Entire shipments go missing in transit.

-

Shortage Claims: Some items are delivered, but others are missing.

-

Delay Claims: Late deliveries that result in lost sales or downstream costs.

With an effective freight claims management strategy, you can recover more money, shorten resolution times, and uncover issues that lead to recurring claims, helping you strengthen your business processes and protect your bottom line.

The Freight Claims Process

When something goes wrong with a shipment, your next step is to begin the freight claims process. Having a clear understanding and consistent approach to managing claims helps you recover faster, reduce internal friction, and avoid costly mistakes that can lead to claim denials.

Here’s how a typical freight claim should be handled:

1. Identify and Report the Issue

Inspect the shipment as soon as it arrives. If there’s damage, a shortage, or something missing, make a note on the proof of delivery (POD) or bill of lading (BOL) in a timely manner. Without swift action and reporting, carriers are more likely to deny your claim.

2. Collect All Documentation

Relevant documentation is the backbone of a successful claim. Generally, you’ll need:

-

Bill of Lading

-

POD with damage or shortage noted

-

Commercial invoice

-

Photographic evidence

-

A written claim with itemized losses

Make sure everything matches. Discrepancies between documents are one of the most common causes of denials.

3. File the Claim Promptly

Each carrier operates under strict time limits. Motor and rail carriers generally allow up to 9 months to file a claim under the Carmack Amendment. Ocean carriers, governed by COGSA, may allow as little as 3 days. Filing early improves your chances of resolution and avoids time-barred denials.

4. Track and Communicate

Stay on top of the claim status. Following up with the carrier helps you avoid delays and shows you’re engaged if additional documentation or clarification is needed.

5. Resolve or Escalate

If your claim is approved, great. If it’s denied or underpaid, be ready to appeal or escalate the case with more evidence, your insurance provider, or legal support if needed.

How to Recover More—and How Zero Down Makes It Easier

Freight claims management works best when it’s proactive, not reactive. That means centralizing your process, using your data, and eliminating the manual work that slows teams down.

Each of the following strategies helps you recover more and prevent future claims, and shows how Zero Down’s platform is built to support them every step of the way.

Centralize your claims process

One of the biggest challenges in freight claims management is fragmentation. Many teams still juggle spreadsheets, emails, and cloud folders, which leads to missing documentation, delayed filings, and increased administrative burden.

Zero Down’s claims platform brings everything into one place, including:

-

Documents

-

Timelines

-

Communication

-

Status Updates

That way, nothing falls through the cracks.

With built-in automation and role-based access, your team can move faster and more accurately from day one.

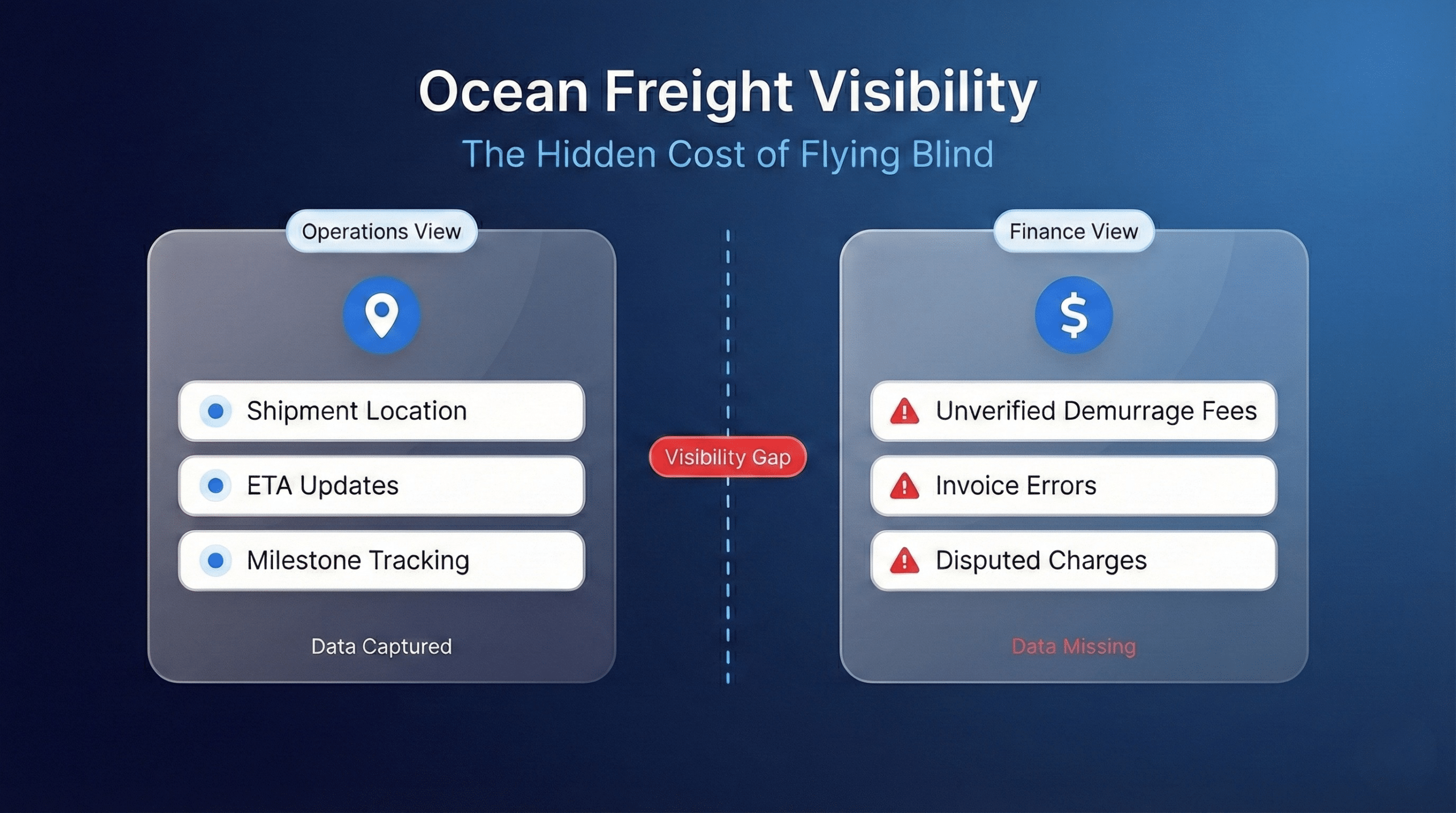

Use your data to reduce costs

Every claim you file reveals something about your supply chain. Which products are consistently damaged? Which lanes or DCs have higher risk? Which carriers are costing you more in hidden expenses?

Our platform gives you real-time dashboards and reporting tools that turn claims into operational insight. You’ll get carrier scorecards, SKU-level damage trends, and vendor performance metrics that help you renegotiate contracts or fix the root cause before it leads to another claim.

Prevent claims before they happen

The most valuable claims strategy is prevention. With the right visibility, you can identify patterns and catch problems before the next shipment goes out the door.

Zero Down helps you track where claims are coming from and why. Whether it’s packaging problems, transit issues, or inconsistent handling at a specific location, our tools surface the trends and support proactive decisions. Over time, that leads to fewer claims, faster deliveries, and stronger carrier relationships.

Zero Down In Action: How We Recovered $12,000 in 30 days

After not receiving any refunds for their delivery issues, a client came to Zero Down for help. With our advanced logistics platform, FreightOptics™, we identified over 200 eligible freight claims and recovered $12,000 in just 30 days, which is more than they had received in the entire previous year.

Freight Claims Management: A Smarter Way to Protect Your Bottom Line

Freight claims are a necessary part of the logistics and transportation industry, but they don’t have to be a source of constant frustration or lost revenue. With the right process, the right tools, and the right insights, managing freight claims becomes a supply chain performance driver, not just a recovery function.

By centralizing your workflow, using your data to spot root causes, and proactively preventing repeat issues, you protect your margins and improve the customer satisfaction. Zero Down’s platform is built to help you do just that—faster, easier, and with less manual effort.

FAQ

How soon should I file a freight claim?

File as soon as the issue is detected. Carriers may allow 3 to 9 months depending on mode, but waiting reduces your chances of success.

What documents are required to support a claim?

At minimum: BOL, delivery receipt, invoice, photos, and a written claim. Additional documentation may be needed based on carrier requirements.

Can I automate the freight claims process?

Yes. Zero Down’s freight claims tool automates file uploads, workflows, alerts, and tracking, saving you time and improving accuracy.

What if a claim is denied?

You can often appeal with more documentation or clarification. If needed, escalate to legal or insurance support depending on the terms.