Supply chain visibility isn’t just a buzzword; it’s the key to successful supply chain operations in today’s unpredictable world. However, only 24% of supply chain professionals reported visibility into 75–100% of their shipments in a 2024 Tive survey, underscoring that a true end-to-end view across the entire supply chain remains rare. While new technologies like AI-enabled control towers are making inroads, persistent barriers to sharing supply chain data mean full real-time tracking across a complex supply chain network is a significant challenge. For supply chain leaders, knowing why supply chain visibility is important and how to implement it effectively can set a resilient supply chain apart from the competition. This guide outlines the essentials to help you stay ahead.

Key Takeaways

- Resilience and Adaptability: In volatile markets, supply chain visibility enables real-time responses to disruptions and meets rising customer expectations for transparency and proactive communication.

- Integration and Technology: Effective visibility relies on integrating data capture, advanced analytics, and innovative technologies to improve decision-making for all the partners involved.

- Tangible Benefits: Implementing supply chain visibility solutions leads to significant cost reductions, improved operational efficiency, enhanced risk management, and increased customer satisfaction.

What is supply chain visibility?

Supply chain visibility is the real-time ability to track orders, inventory, and shipments across suppliers and carriers, turning raw data collection into predictive ETAs and automated processes for exception management. It provides stakeholders with the timely and accurate information needed to make smarter, more proactive decisions regarding all supply chain activities.

Benefits of Supply Chain Visibility

Implementing a robust visibility strategy yields extensive benefits across cost, service, and risk management.

- Financial Improvements: MIT research indicates digital transformation can reduce costs by up to 50% and lift revenue by ~20%. These cost savings are a primary driver, as a 2024 Boston Consulting Group survey found 65% of executives were prioritizing reductions in their company’s logistics and manufacturing costs.

- Improved Operational Efficiency: Real-time monitoring and data analytics from platforms like FreightOptics allow leaders to refine supply chain processes, minimize waste, and streamline operations, shifting from reactive problem-solving to proactive strategic planning. This is a cornerstone of effective supply chain management.

- Enhanced Risk Management: Early detection of potential disruptions allows businesses to identify vulnerabilities and respond with precision, protecting both logistics operations and customer relationships from issues like inventory shortages.

- Increased Customer Satisfaction: In 2025, 66% of consumers report being affected by poor delivery experiences, and 79% among ages 18–35. Proactive communication and accurate expected delivery dates are critical for meeting consumer demand and building loyalty.

- Greater Sustainability: With 85% of global CxOs having increased sustainability investments in the past year (Deloitte 2024), improved visibility helps optimize resource use, cutting fuel consumption and demonstrating a commitment to environmentally responsible business operations.

| Before Visibility (The Old Way) | After Visibility (The New Standard) |

| Manual processes & phone calls | Automated, real-time exception handling |

| Static, unreliable ETAs | AI-driven, predictive ETAs |

| Reactive response to delays | Proactive disruption management |

| Fragmented data in silos | Unified data in a central dashboard |

| High administrative overhead & shipping costs | Increased supply chain efficiency |

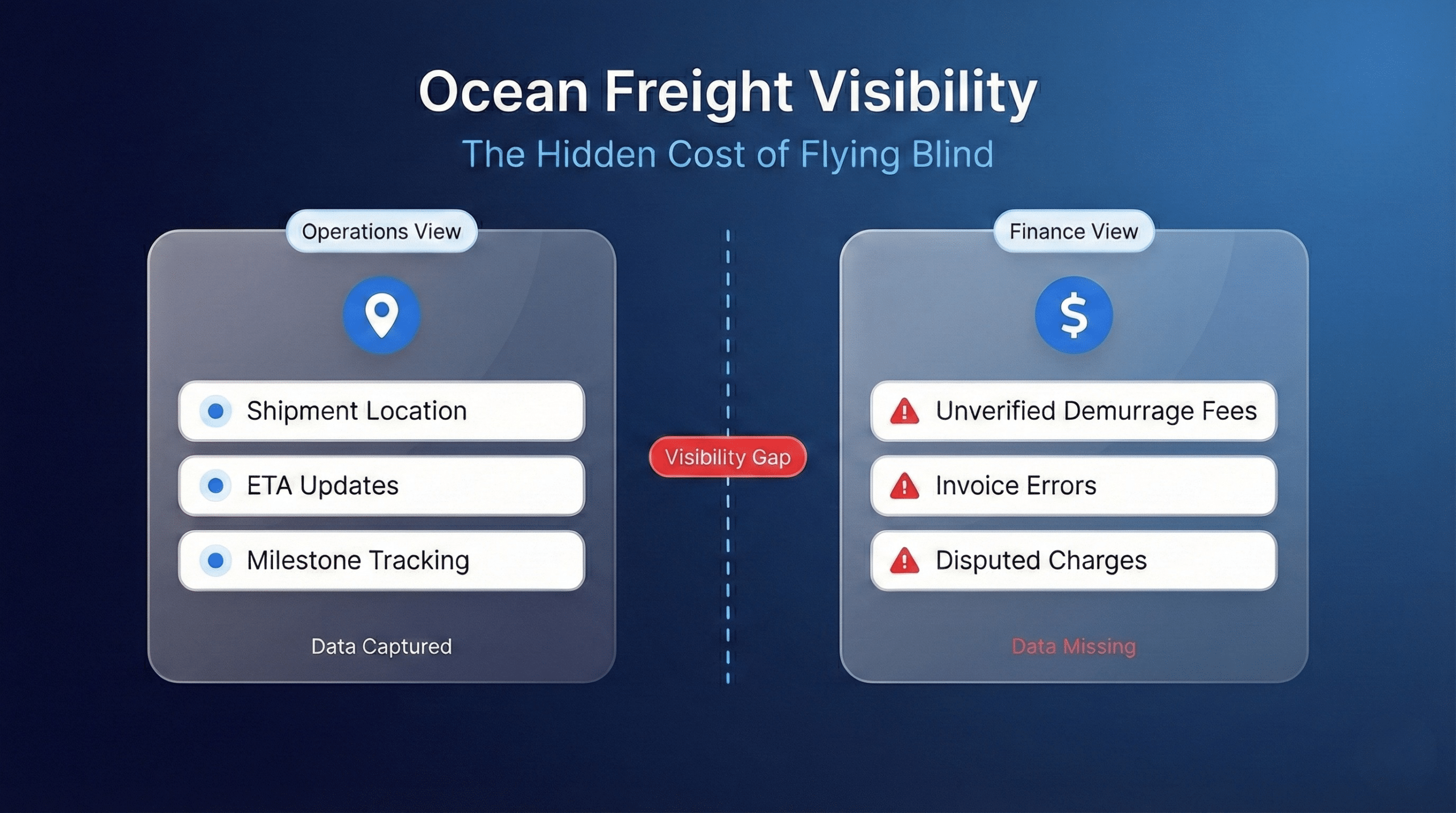

Challenges & Gaps in Achieving Full Visibility

While the benefits are clear, several obstacles prevent companies from being able to achieve supply chain visibility fully.

- Multi-Tier Visibility: Gaining visibility beyond Tier-1 suppliers into a diverse supplier network of raw materials providers and their logistics networks is exceptionally difficult.

- Data Silos: Information is often trapped in disparate systems like Enterprise Resource Planning (ERP), WMS, and TMS across different trading partners, preventing a single source of truth.

- Carrier Coverage & Integration: Not all carriers offer reliable, real-time data feeds, and integrating the hundreds of potential supply chain partners globally is a massive technical challenge.

- Data Quality and Standardization: Inconsistent data and inaccuracies from suppliers data can corrupt analytics and lead to poor decision-making.

Technologies That Enable Visibility

A suite of modern technologies and software tools forms the backbone of today’s leading visibility solutions.

- Control Towers: Centralized, AI-enabled dashboards that aggregate data from multiple sources to provide a holistic view of the supply chain, predict disruptions based on key trends, and deliver real-time insights.

- APIs & EDI: Application Programming Interfaces (APIs) and Electronic Data Interchange (EDI) are the connective tissues that allow seamless data integration between the systems of shippers, carriers, and other partners.

- IoT/RFID: Internet of Things (IoT) sensors and Radio Frequency Identification (RFID) tags provide granular data on the location, condition, and status of goods as they move through the supply chain.

- AI & Machine Learning: Artificial intelligence and machine learning analyze vast datasets hosted via cloud computing to predict demand trends, identify hidden risks, and automate routine decision-making, turning raw data into actionable intelligence.

Regulations Driving Visibility (2024–2026)

New regulations are elevating the importance of regulatory compliance, making traceability and supplier transparency an imperative.

| Regulation (Acronym) | Region | Core Requirement | Key Dates |

| CSDDD / CS3D | EU | Mandates human rights & environmental due diligence across value chains. | Entered into force July 25, 2024 (phased implementation). |

| EUDR | EU | Requires geolocation data to prove key commodities are deforestation-free. | Main applicability from Dec 30, 2025 (SMEs from June 30, 2026). |

| UFLPA | U.S. | Prohibits imports tied to forced labor from Xinjiang; demands high traceability. | 2025 strategy update expands enforcement sectors. |

KPIs to Measure Supply Chain Visibility

Measuring the impact of visibility initiatives is crucial for tracking supply chain performance. Key Performance Indicators (KPIs) to track include:

- On-Time In-Full (OTIF): The percentage of orders delivered with the correct quantity of goods, to the right location, at the right time.

- On-Time Delivery (OTD): A measure of delivery performance.

- Exceptions per 1,000 Shipments: The rate of unplanned events that require manual intervention.

- Lead-Time Variability: The consistency of the time it takes from order placement to final delivery.

- Dwell Time: The amount of time assets or inventory sit idle at a node (e.g., warehouse, port).

- Inventory Accuracy: How well records match physical stock, which helps monitor inventory levels and prevent inventory shortfalls.

How to Achieve Supply Chain Visibility: A 6-Step Roadmap

To improve supply chain visibility, a phased approach is essential. Selecting the right supply chain visibility tools, focusing on features like seamless integration, advanced analytics, and an intuitive UI, is the first step. From there, follow this roadmap.

- Establish a Baseline and Map Critical Lanes: Audit your current warehouse management processes and data sources to identify the biggest visibility gaps. Map your most critical and problematic shipping routes and set baseline KPIs to measure current performance.

- Integrate Core Data Feeds: Begin connecting your primary carriers and internal systems (TMS, ERP) to a central platform. The goal is to unify carrier feeds via API or EDI to create a single source of truth.

- Pilot on a Small Scale: Test the new visibility solution on a controlled scale by piloting two or three critical lanes. This proves the concept and demonstrates value before a full rollout.

- Expand and Scale Across the Network: After a successful pilot, gradually roll out the solution across more carriers, regions, and business units. Review the pilot results after 30 days to inform the expansion plan.

- Automate Exception Management and Alerts: Configure the system to handle common issues automatically. Enable automated alerts to notify teams of critical events that require manual intervention.

- Embed Visibility into S&OP: Fully integrate visibility data into your Sales and Operations Planning (S&OP) process to drive more strategic, data-informed decisions across the entire business.

Real-World Supply Chain Visibility in Action

Success stories highlight the transformative power of better visibility. For example, vendor-specific platforms like ZeroDown’s FreightOptics™ have helped companies uncover hidden accounts and unify transportation data. On a broader scale, major shippers like Renault Group are partnering with platforms like Shippeo and Google Cloud to deploy AI-powered control towers for predictive, multi-modal visibility. This demonstrates the industry-wide shift toward leveraging integrated technology for a competitive edge.

Glossary of Key Terms

- Control Tower: A centralized dashboard that provides a comprehensive, real-time view of the entire supply chain.

- Predictive ETA: An estimated time of arrival calculated using AI and machine learning, which is more accurate than static ETAs.

- EDI/API: Technologies that enable different software systems to communicate and exchange data automatically.

- IoT/RFID: Devices that transmit real-time data about the location and condition of physical assets.

- OTIF: (On-Time In-Full) A key performance indicator measuring if an order was delivered as promised.

- Multi-Tier Visibility: The ability to see beyond direct (Tier-1) suppliers to their suppliers (Tier-2, Tier-3, etc.).

Conclusion: Visibility is Crucial

For any modern supply chain management strategy, enhanced visibility offers numerous benefits. By implementing the right solution, businesses can harness real-time data, foster collaboration, and integrate seamlessly with existing systems. For supply chain managers, embracing the potential of chain visibility is no longer optional; it is an essential tool for navigating the complexities of global supply chains and ensuring your business thrives in an ever-evolving market.

FAQ

What is supply chain visibility?

Supply chain visibility is the ability to track orders and shipments in real time across the entire logistics network, using data to predict outcomes based on customer demand and manage exceptions.

What’s the difference between supply chain visibility and transparency?

Visibility is about seeing the real-time location and status of goods (the “where”). Transparency is about understanding the “what,” “how,” and “why” behind the processes, including sourcing, labor practices, and environmental impact.

How does AI improve supply chain visibility?

AI enhances visibility by analyzing vast amounts of data to produce highly accurate predictive ETAs, identify potential disruptions before they occur, and recommend optimal solutions to logistics challenges.

Which KPIs measure supply chain visibility success?

Key KPIs like OTIF, exceptions per shipment, lead-time variability, and inventory accuracy help business leaders track supply chain performance and ensure efficiency, reliability, and cost-effectiveness.

How do new regulations (EUDR, CSDDD, UFLPA) affect visibility requirements?

These regulations require companies to provide verifiable proof of due diligence deep within their value chains, making multi-tier visibility essential for compliance and market access.